Research lines

In-situ and 3D characterization

Seeing through metals: a 3D EBSD analysis of twinning in Mg alloys

Recent progress in the development of 3D characterization techniques is paving the way to a more comprehensive understanding of the relationship between the microstructure and the properties of engineering materials. 3D electron backscatter diffraction (3D-EBSD), combining 2D EBSD software with the milling capabilities of a focused ion beam (FIB) and a field-emission gun scanning electron microscope (FEG-SEM), is able to provide a three dimensional characterization of the morphology and the orientations of individual grains as well as a full description of grain boundaries (misorientation, boundary plane).

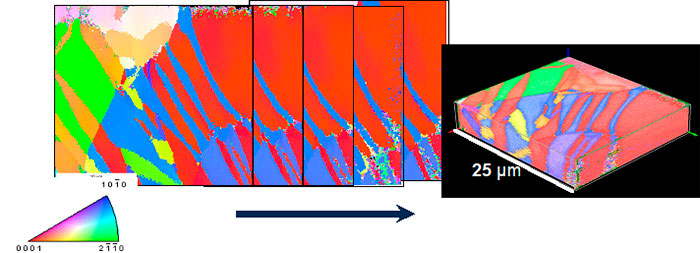

Sequence of 2D EBSD maps obtained by consecutive FIB milling and EBSD mapping steps in a Mg AZ31 alloy. 3D recostruction.

We are exploiting the capabilities of 3D-EBSD to better understand the fundamentals of twinning in Mg alloys. Recent work in collaboration with the University of Oxford, UK, and the Max Planck Institute in Stuttgart, Germany, has yielded new insights about twin nucleation, twin propagation and twin morphology in magnesium alloys (More details can be found @ Fernández, Jérusalem, Gutiérrez-Urrutia, Pérez-Prado, Acta mater. 2013).

This research was carried out in the frame of a CENIT program (MAGNO2008-1028-CENIT, Spanish Ministry of Economy and Competitiveness), led by the Antolín Group.