MNG GROUP

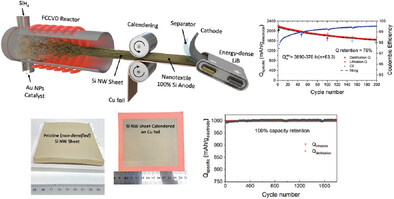

The Multifunctional Nanocomposites Group, is an independent research group at IMDEA Materials, founded by the PI in 2011. The group is highly multidisciplinary and draws people with backgrounds in physics, electrochemistry, chemical engineering, aerosol science and nanotechnology. Its prime focus is to study methods for the synthesis and assembly of 1D nanomaterials into macroscopic structures with high-performance properties for energy and transport applications. The group pursues research of excellence that contributes to the professional development of its members.

The overall aim of the group’s research is to exploit the superlative properties of high aspect ratio nanoparticles while also using their network organization to produce solids with distinct properties from those of monolithic structures. The work of the group is broadly divided into four research areas: i) synthesis and assembly of 1D nanomaterials, ii) nanostructured electrodes for energy, iii) mechanics of nanostructured networks and their composites, and iv) multifunctional materials.

Social Networks

Follow us on Twitter @MNGMaterials for more updates and exciting news!