ULTRAFINE EUTECTICS BY LASER ADDITIVE MANUFACTURING (ELAM)

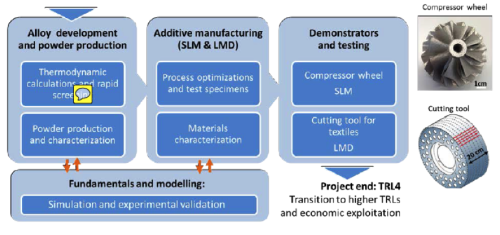

The proposed project aims at developing new high strength eutectic alloys by laser-based additive layer manufacturing (ALM) using selective laser melting and laser metal deposition based on Ti-TiFe and Fe-Fe2Ti eutectics. These laser-based ALM methods possess inherently high cooling rates and are, thus, ideal for processing ultrafine eutectics and hierarchically structured near-eutectic alloys including Ti-Fe-Sn-Nb, Ti-Fe-Co, Fe-Ti-Si, Fe-Ti-Zr-B and other eutectic alloys. Although being the subject of research for decades and showing remarkable mechanical properties, none of these alloys is currently relevant for industrial applications since no economically and technically viable processing route exists. This proposal represents the first attempt to produce ultrafine Ti- and Fe-eutectics by ALM, spanning activities along the entire manufacturing chain from fundamental materials development, powder production, ALM process and post-treatment developments to demonstrator testing.

- PI IMDEA: Dr. F. Sket (MT Pérez-Prado, S. Milenkovic, team members)

- Funding: 1.639.600 € (IMDEA, 150.000 €)

- Duration: 2017-2020

- Agency: M-era.NET call 2016 (EU).

- Partners: DLR (coordinator) (Germany), Access (Germany), Imdea Materials (Spain), Fraunhofer ILT (Germany), Wigner RCP (Hungary), Bosch-Mahle Turbosytems (Germany), P&G Manufacturing (Germany).