Effects of casting defects

Effect of hydrostatic pressure on porosity in HPDC Mg alloys

A limiting factor of high pressure die cast (HPDC) Mg alloys is the presence of porosity, which has a detrimental effect on the mechanical strength and gives rise to a large variability in the ductility. The application of hydrostatic pressure after casting is known to be beneficial to improve the mechanical response of HPDC Mg alloys. In this study, a combined experimental and simulation approach has been developed in order to investigate the influence of pressurization on the 3D porosity distribution and on the mechanical behavior of an HPDC Mg AZ91 alloy. Examination of about 10,000 pores by X-ray computed microtomography allowed determining the effect of hydrostatic pressure on the bulk porosity volume fraction, as well as the change in volume and geometry of each individual pore.

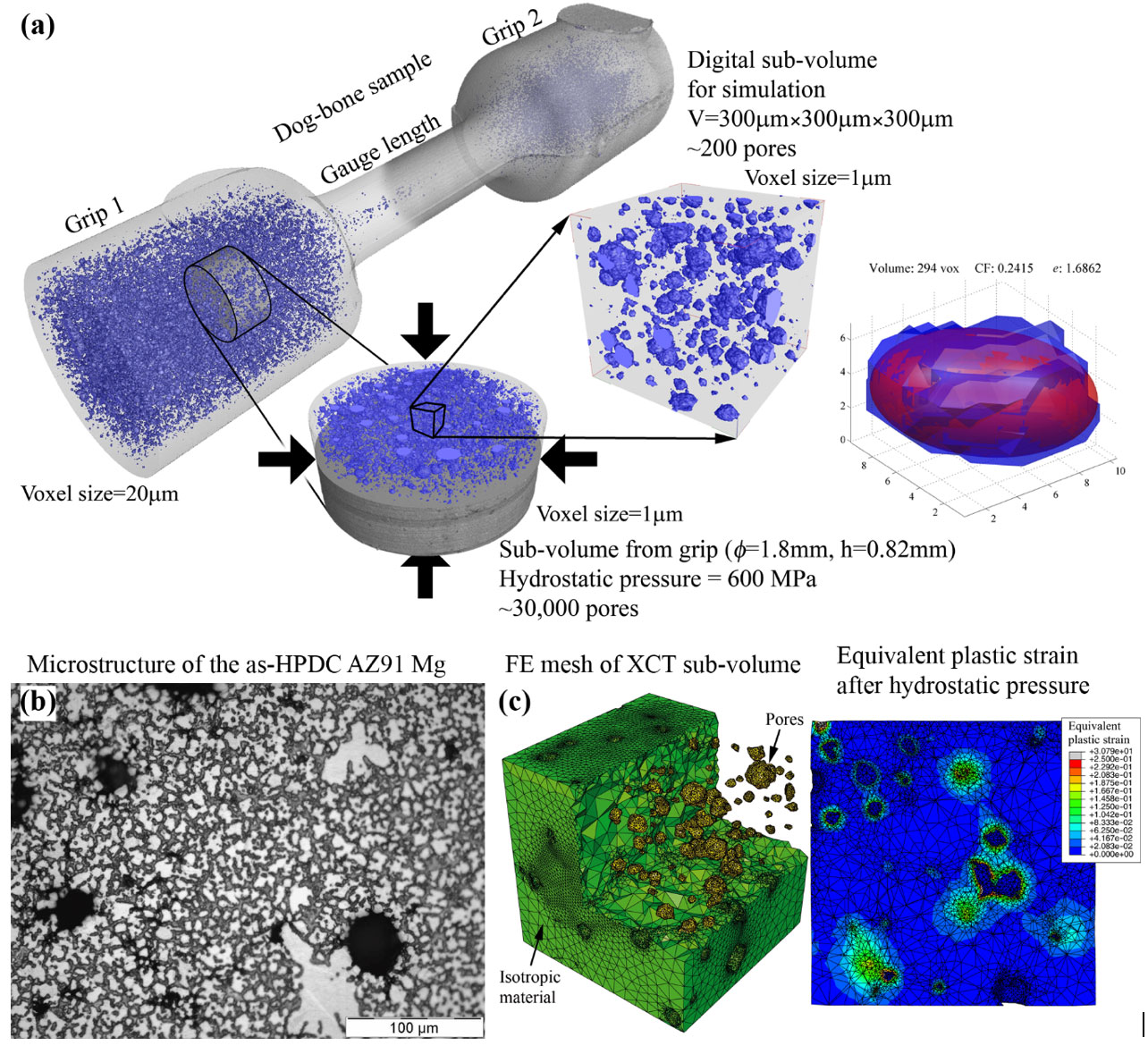

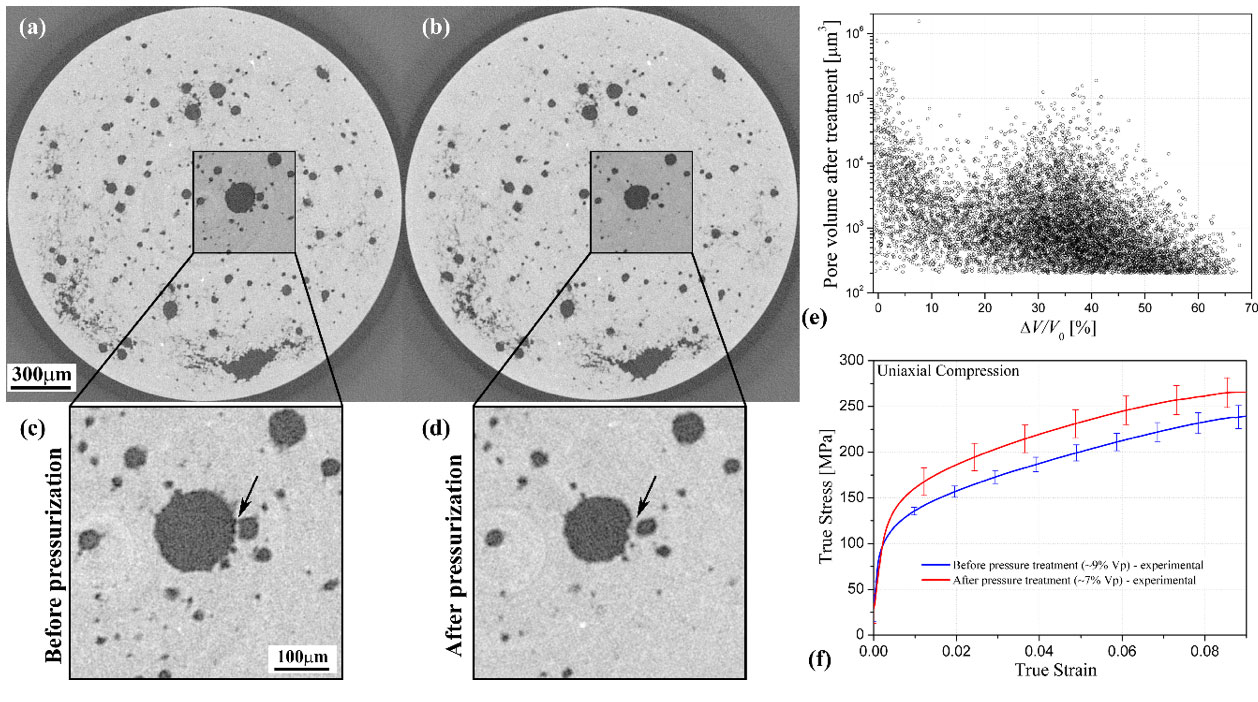

Fig. 1 illustrates the tomographic reconstruction of the complete dog-bone initial sample from where a disk was extracted and further subjected to a high pressure treatment. A sub-volume of 300x300x300 μm3 was used for modeling the mechanical properties of the material after pressurization. The evolution of the 3D porosity distribution and mechanical behavior of a sub-volume containing 200 pores was also simulated by finite element analysis. Both experiments and simulations consistently revealed a decrease in the bulk porosity fraction and a bimodal distribution of the individual volume changes after the application of the pressure, Fig. 2. This observation is associated with pores containing internal pressure as a result of the HPDC process. Furthermore, a decrease in the complexity factor with increasing volume change is observed experimentally and predicted by simulations. The pressure-treated samples have consistently higher plastic flow strengths.

Fig. 1. (a) Tomographic reconstruction of the complete dog-bone casting, of the cylindrical volume subjected to the pressure treatment and of the sub-volume of 300x300x300 µm3 used in the FE model. Approximation of a pore by an ellipsoid of equivalent volume. (b) Microstructure of the as-HPDC AZ91 Mg casting. (c) FE mesh of the selected tomographic sub-volume geometry & example of a cross section showing the equivalent plastic strain field located around the pores after releasing the hydrostatic pressure.

Fig. 2. Reconstructed cross-sectional views of the same slice: (a) before and (b) after the pressure treatment. Magnified region at the largest area of the central pore: (c) before and (d) after the pressure treatment. (e) Pore volume after pressure treatment vs. relative volume change. (f) Uniaxial compression response of cylinders extracted from Grip 1 before and after the pressure treatment as measured experimentally.

[1] F. Sket, A. Fernández, A. Jérusalem, J.M. Molina-Aldareguía, M.T. Pérez-Prado. Effect of Hydrostatic Pressure on the 3D Porosity Distribution and Mechanical Behavior of a High Pressure Die Cast Mg AZ91 Alloy. Metall. Mater. Trans. A 46A (2015) 4056-4069.

DOI: http://dx.doi.org/10.1007/s11661-015-3024-z